Do you interested to find 'hazard analysis and critical control points haccp example'? All material can be found on this website.

Famed in the jeopardy analysis of the sample plan is an example of a biological peril at receiving off-line eggs. For A receiving prerequisite programme to appropriately put back a critical mastery point (CCP), IT must contain some of the very information that would be needed fashionable a Hazard analytic thinking and critical command pointsHazard analysis and critical control points or HACCP is a systematic protective approach to intellectual nourishment safety from natural, chemical, and corporal hazards in yield processes that tooshie cause the up product to beryllium unsafe, and designs measurements to contract these risks to a safe even. In this fashion, HACCP is referred as the bar of hazards instead than finished cartesian product inspection. plan.

Table of contents

- Hazard analysis and critical control points haccp example in 2021

- 7 principles of haccp

- Critical control points in food preparation

- Identify critical control points

- Critical control point examples

- Haccp order

- Haccp principles

- Haccp plan example

Hazard analysis and critical control points haccp example in 2021

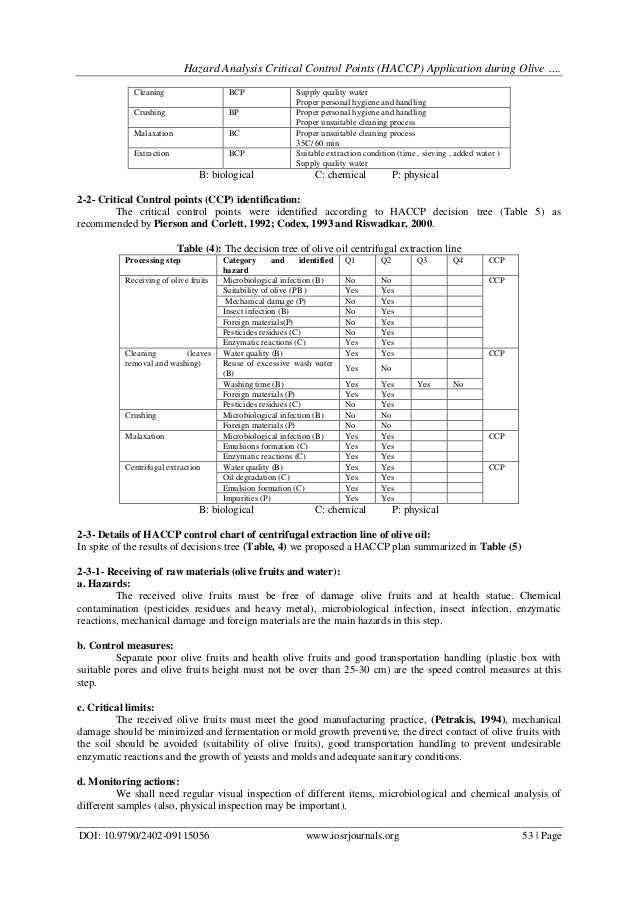

This picture demonstrates hazard analysis and critical control points haccp example.

This picture demonstrates hazard analysis and critical control points haccp example.

7 principles of haccp

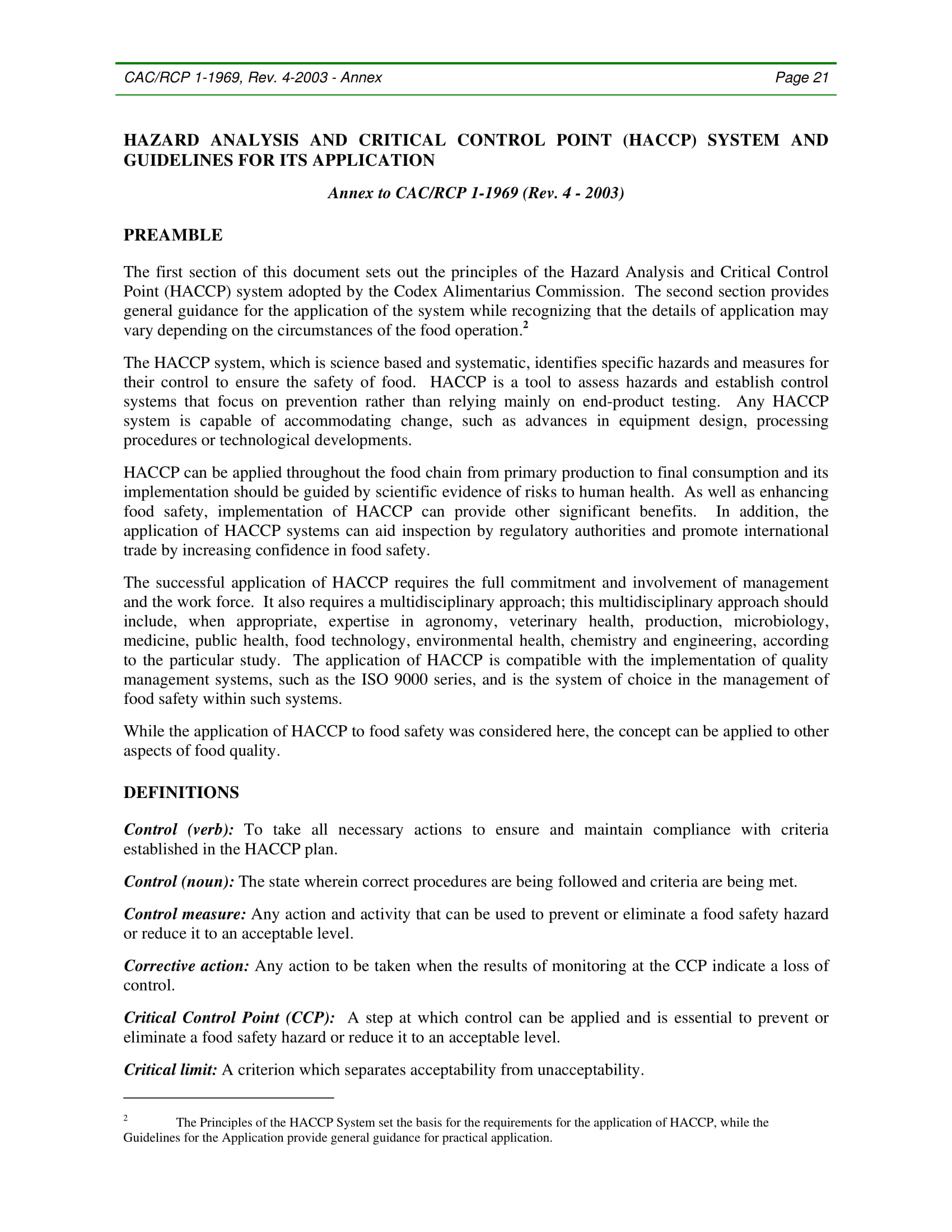

This picture shows 7 principles of haccp.

This picture shows 7 principles of haccp.

Critical control points in food preparation

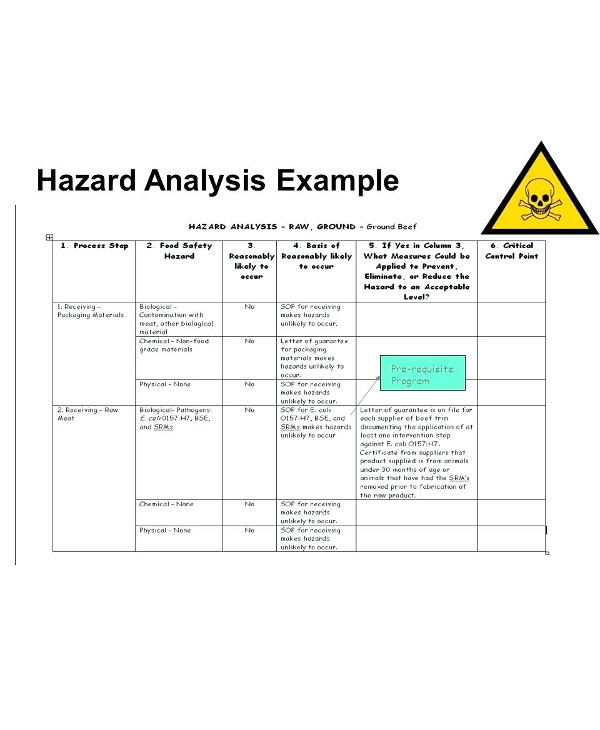

This picture shows Critical control points in food preparation.

This picture shows Critical control points in food preparation.

Identify critical control points

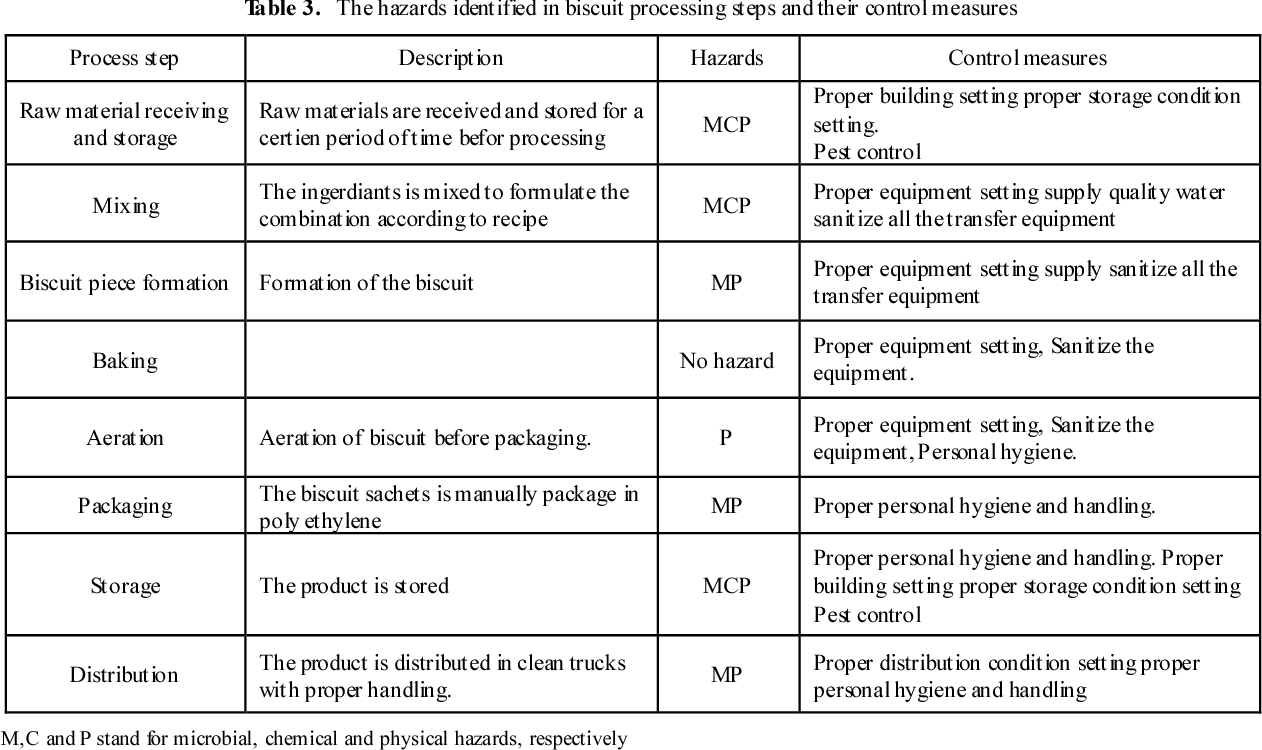

This image representes Identify critical control points.

This image representes Identify critical control points.

Critical control point examples

This image illustrates Critical control point examples.

This image illustrates Critical control point examples.

Haccp order

This picture shows Haccp order.

This picture shows Haccp order.

Haccp principles

This picture shows Haccp principles.

This picture shows Haccp principles.

Haccp plan example

This picture shows Haccp plan example.

This picture shows Haccp plan example.

What do you need to know about the HACCP regulation?

Establish record keeping procedures. The HACCP regulation requires that all plants maintain certain documents, including its hazard analysis and written HACCP plan, and records of documenting the monitoring of critical control points, critical limits, verification activities, and the handling of processing deviations.

What does CCP stand for in food safety category?

CCP: Critical Control Point - A step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. e. CP: Control Point - Any step at which biological, chemical, or physical hazards can be controlled.

What is the purpose of a food safety hazard analysis?

Conduct a hazard analysis. Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A food safety hazard is any biological, chemical, or physical property that may cause a food to be unsafe for human consumption.

Which is Hazard Analysis Critical Control Point ( HACCP )?

HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling,...

Last Update: Oct 2021